Core Technology 1

Reverse Push High Efficiency Denitrification Tank (HRPD)+Aerobic MBR Membrane Tank (AMBR) Process Technology

Core Technology 2

Circulating Anaerobic Ammonia Oxidation Bioreactor (CAAB)+Aerobic MBR Membrane Reactor (AMBR) Process Technology

Core "HRPD+AMBR" technology

Technical principle: There are a large number of aerobic bacteria, nitrifying bacteria, nitrifying bacteria, denitrifying bacteria, and other advantageous microorganisms coexisting regionally in the HRPD tank. The nitrification process is controlled in the NO2- stage to prevent further oxidation of NO2- to NO3-, and NO2- is directly used as the electron acceptor for denitrification. The reverse design allows the denitrification reaction to cycle repeatedly.

The AMBR tank is a comprehensive combination of biological fillers, membrane components, and aeration devices. It has an aerobic reaction function area and a regional MBR membrane separation area, which alleviates blockages caused by high sludge concentration in the MBR membrane, balances the overall sludge concentration, and improves the ability to withstand impact loads.

Technical advantages

① The pollutant removal rate reaches 90-95%;

② Has a high concentration of biological phases and strong resistance to water quality impact loads.

③ 20% reduction in alkali dosage, 30% reduction in denitrification tank volume, and 20% reduction in energy consumption;

④ 40% reduction in carbon sources and 30% reduction in sludge volume;

⑤ Low organic load, long sludge age, and low residual sludge production;

⑥ Efficient solid-liquid separation, good and stable effluent quality, and effluent can be directly reused.

Core "CAAB+AMBR" technology

Technical principle:Especially for municipal wastewater with low carbon to nitrogen ratio characteristics, CAAB technology effectively controls dissolved oxygen, creates the best environment for nitrite nitrogen formation, and creates a reaction substrate for anaerobic ammonia oxidation reaction. At the same time, effective screening and high enrichment of functional microbial communities promote synchronous carbon and nitrogen metabolism within the system, ensuring stable total nitrogen compliance and reducing the addition of organic carbon sources. Avoiding the impact of organic matter on microbial communities and improving removal efficiency through cyclic reactions. The AMBR technology ensures stable acquisition of a large amount of nitrite nitrogen in the anaerobic ammonia oxidation reaction substrate through internal reflux to the front end, achieving a new process system for precise acquisition, intelligent analysis, and targeted regulation of pollutant degradation throughout the entire process.

Technical advantages:

① The efficiency of producing nitrite nitrogen is stable and efficient;

② Under low carbon to nitrogen ratio conditions, anaerobic ammonia oxidation synergistically removes nitrogen, saving 80% of organic carbon sources and 80% of aeration energy consumption;

③ Reduce sludge production by about 50% during the degradation stage;

④ Repeated cyclic reflux circulation can increase the efficiency of denitrification reaction by multiple times;

⑤ Efficient and scientific implementation of targeted and reasonable regulation throughout the entire process.

⑥ Reducing sludge production and greenhouse gas emissions is of great significance and research value for the development of wastewater denitrification technology.

Application scope: rural areas, hotels, communities, hospitals, schools, scenic areas, highway service areas, airport service areas, high-speed rail stations, river interception, and low-carbon nitrogen ratio municipal sewage.

Effluent quality

BOD5: 6mg/L, CODcr: 30mg/L, ammonia nitrogen: 0.5mg/L, total nitrogen: 5mg/L, and total phosphorus: 0.5mg/L.

-

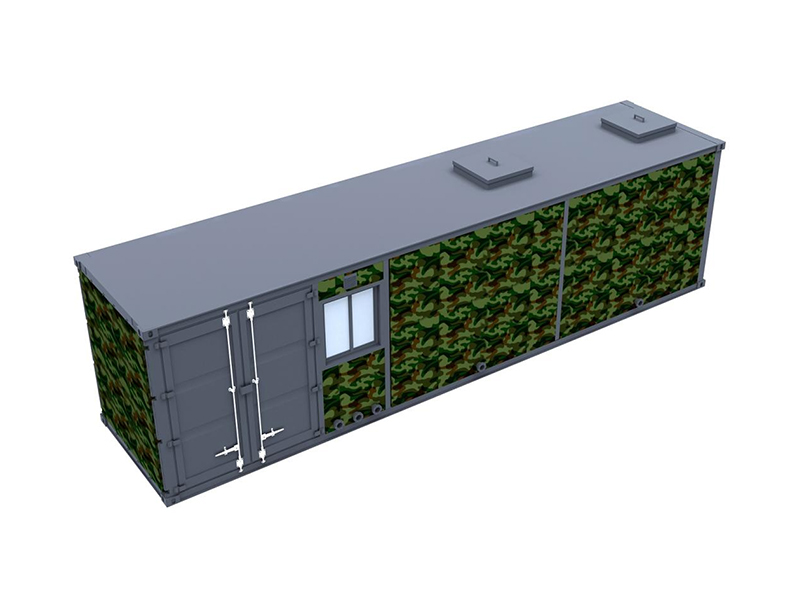

Equipment Technology Introduction - Domestic Sewage Treatment and Reuse Equipment

-

Industrial pure water treatment equipment

-

Equipment Technology Introduction - Organic Wastewater Treatment Equipment

-

Groundwater softening device

-

Intelligent integrated prefabricated pumping station

-

Smart construction site mud water treatment technology and integrated equipment

-

Groundwater iron and manganese removal filter

-

Potable water equipment

-

Smart water management