Description

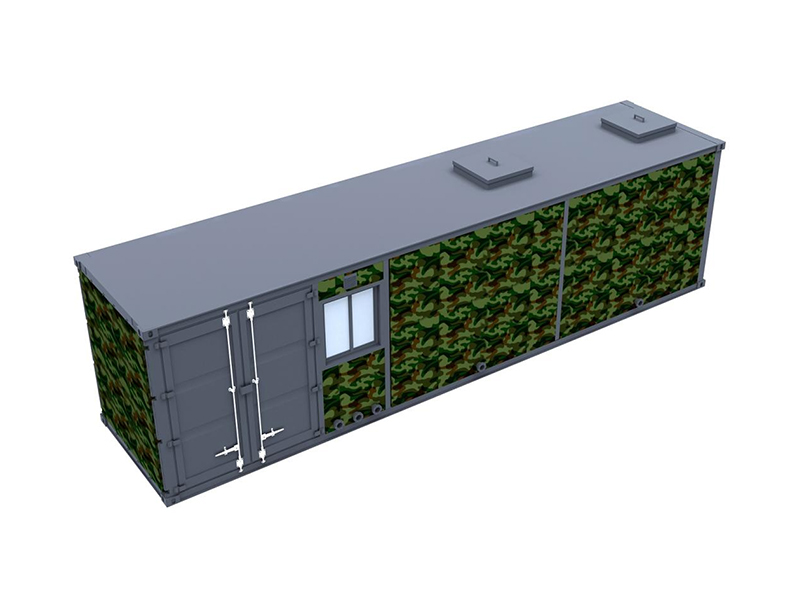

Our company's intelligent construction site mud and water treatment integrated equipment was applied for and obtained a Chinese utility model patent in 2020. At present, there are multiple models to choose from to adapt to customers with different mud water treatment volumes and needs. The integrated equipment for mud and water treatment on smart construction sites integrates PLC control cabinets, surge flow high-efficiency flocculation tanks, surge flow high-efficiency coagulation aid tanks, and other facilities, with a high degree of integration. Under fully automatic operation conditions, efficient treatment of mud water can be achieved, and the effluent can meet the standard for direct discharge.

Core technology

Main features

1. Mobile convenience: After completing the phased processing requirements, the device can be transferred, reinstalled, and used;

2. Efficiency: The surge type high-efficiency coagulation technology accelerates the reaction speed and reduces the dosage of chemicals;

3. Intelligence: Equipped with PLC and cloud platform technology, achieving remote control and unmanned operation;

4. Reusability: The use of reclaimed water reuse devices reduces the water consumption on construction sites and saves water costs.

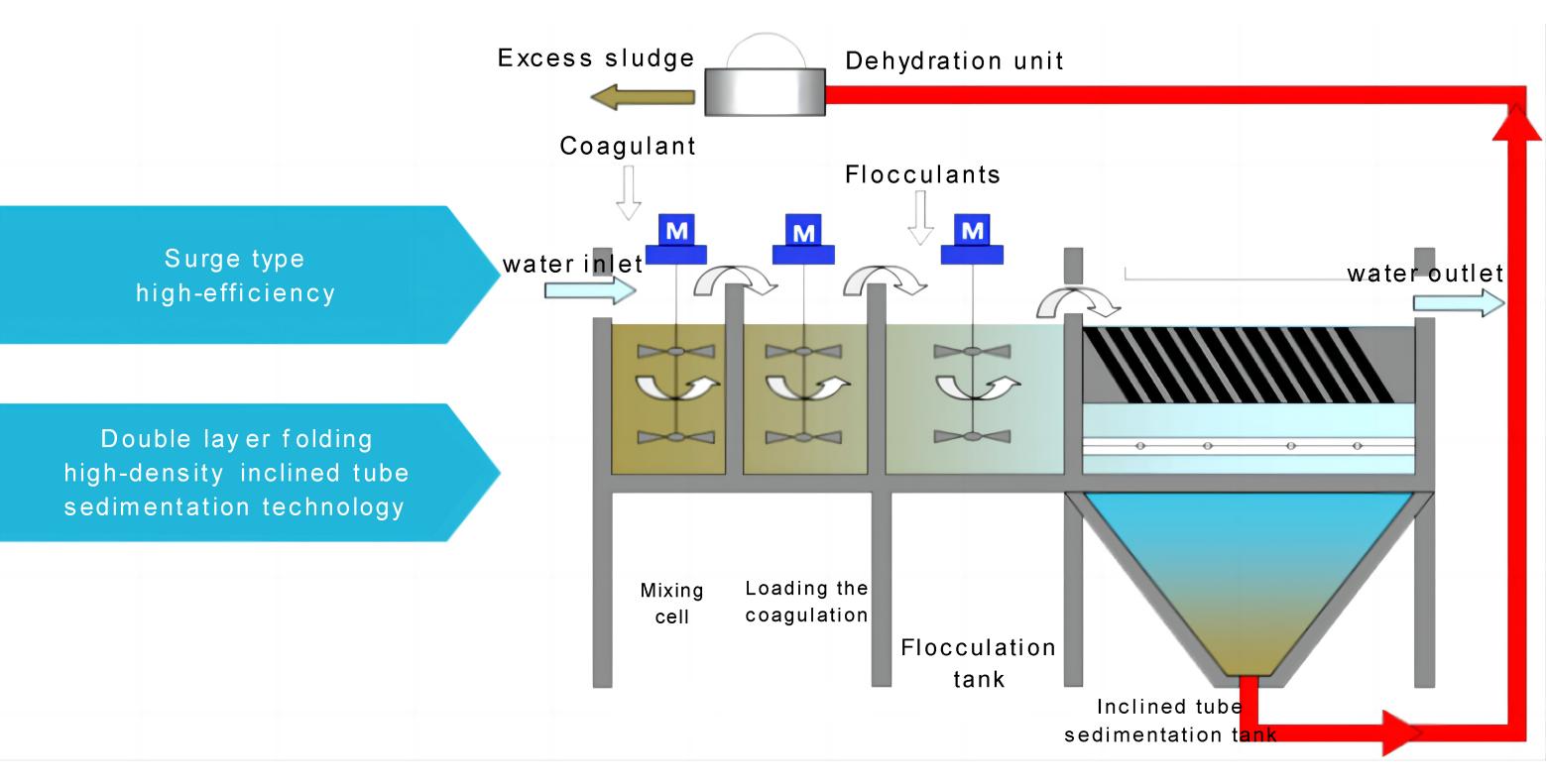

Technological process

The construction site mud water enters the surge type high-efficiency flocculation tank through a lifting pump. The surge type high-efficiency flocculation tank uses a surge device and PAC dosing device to fully contact the mud water with PAC, and then enters the surge type high-efficiency flocculation tank through a diversion hole. The surge type high-efficiency coagulation tank uses a surge device and PAM dosing device to fully contact the mud water with PAM. The mud water in full contact with PAM and PAC enters the high-density inclined tube sedimentation tank for sedimentation.

Equipment specifications

|

Equipment model |

Excavation area(hm2) |

Design water volume (m3/h) |

Floor area (m2) |

Equipment structure |

|

ST-NJ-1 model |

<0.5 |

30 |

30 |

Container frame structure (integrated with 1 unit) |

|

ST-NJ-2 model |

0.5-1 |

60 |

60 |

Container frame structure (integrated with 2 unit) |

|

ST-NJ-3 model |

1-2 |

120 |

120 |

Container frame structure (integrated with 3 unit) |

|

ST-NJ-4 model |

>2 |

>120 |

>120 |

Container frame structure (integrated with multiple units) |

Application scenarios and advantages

Suitable for the treatment of mud and water in various construction sites, it has the advantages of achieving direct discharge standards, high treatment efficiency, low treatment cost, intelligent integration, and small volume:

1. Direct discharge meets the standard: the process is optimized, and the mud water treatment can meet the standard for direct discharge. The effluent can be reused for construction, dust removal, and cleaning water at the construction site of the project;

2. High processing efficiency: The use of surge type high-efficiency coagulation technology has accelerated the reaction speed, and the use of high-density inclined tube sedimentation technology has greatly improved the sedimentation efficiency;

3. Low processing cost: Compared to traditional processing methods, it saves an average of 70% in processing costs.

4. Intelligent integration: highly integrated, capable of fully automatic operation, and equipped with a cloud platform for real-time monitoring;

5. Small size: Compared to the self built pre-treatment facilities on the construction site, it greatly reduces the occupied area and construction time;

6. Mobile: The device is mobile and can be reused to save costs.

-

Equipment Technology Introduction - Domestic Sewage Treatment and Reuse Equipment

-

Industrial pure water treatment equipment

-

Equipment Technology Introduction - Organic Wastewater Treatment Equipment

-

Groundwater softening device

-

Intelligent integrated prefabricated pumping station

-

Smart construction site mud water treatment technology and integrated equipment

-

Groundwater iron and manganese removal filter

-

Potable water equipment

-

Smart water management