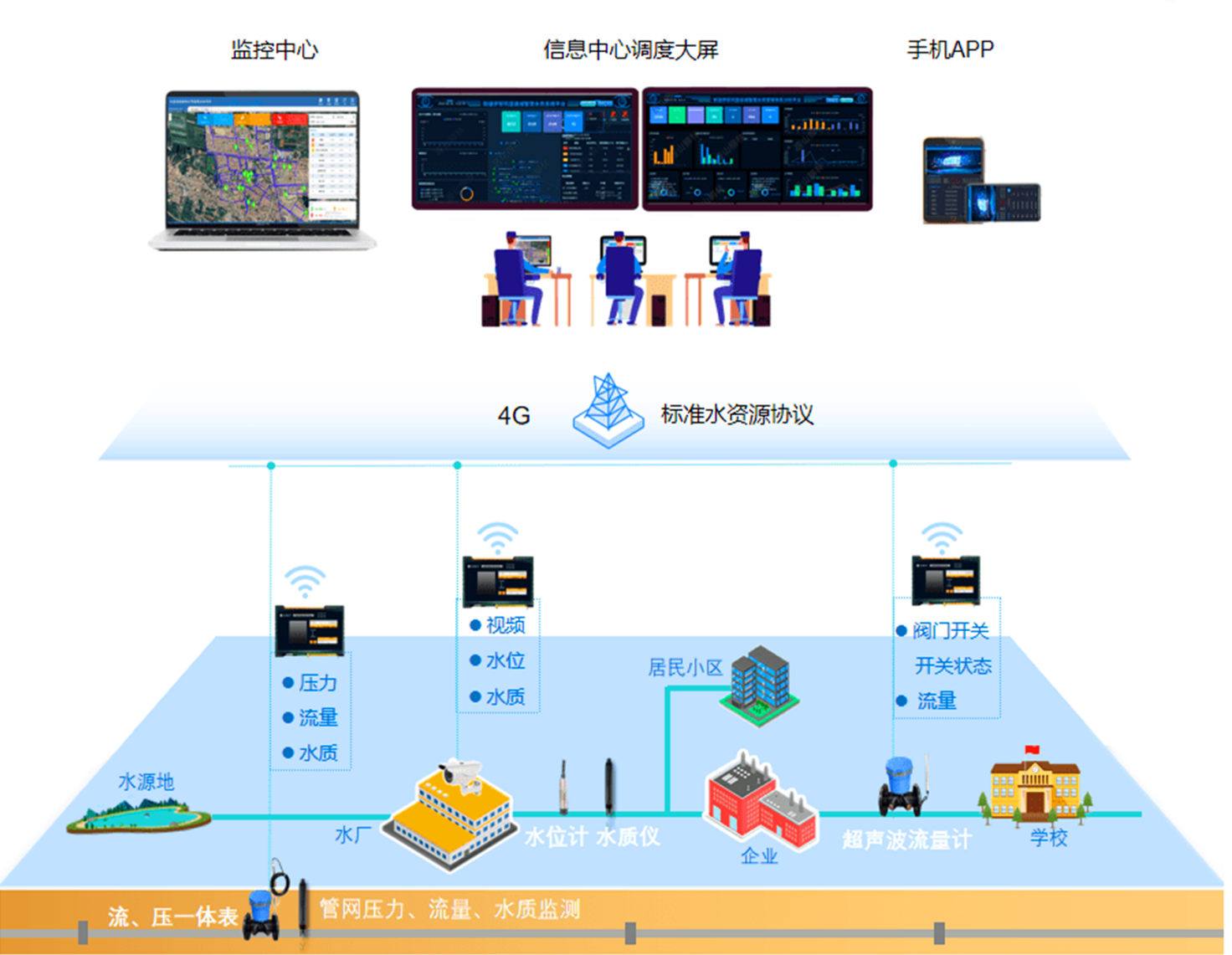

Intelligent Cloud Platform System

Realize the "smart supervision", "smart production", "smart pipeline network" and "smart decision-making" of the water business system, ensure the safe operation of water facilities, and make water business operations more efficient, management more scientific, and services more high-quality.

System Introduction

(1) Smart regulatory system: equipped with an integrated monitoring platform, big data center, and IoT platform;

(2) Smart production system: equipped with raw water monitoring platform, water plant production monitoring platform, and secondary water supply monitoring platform;

(3) Smart pipeline system: equipped with water supply pipeline geographic information system, water supply pipeline monitoring system, and DMA pipeline leakage control system;

(4) Smart decision-making system: equipped with a business fee system and a mobile app.

Schematic diagram of cloud platform supervision system

Schematic diagram of cloud platform supervision system

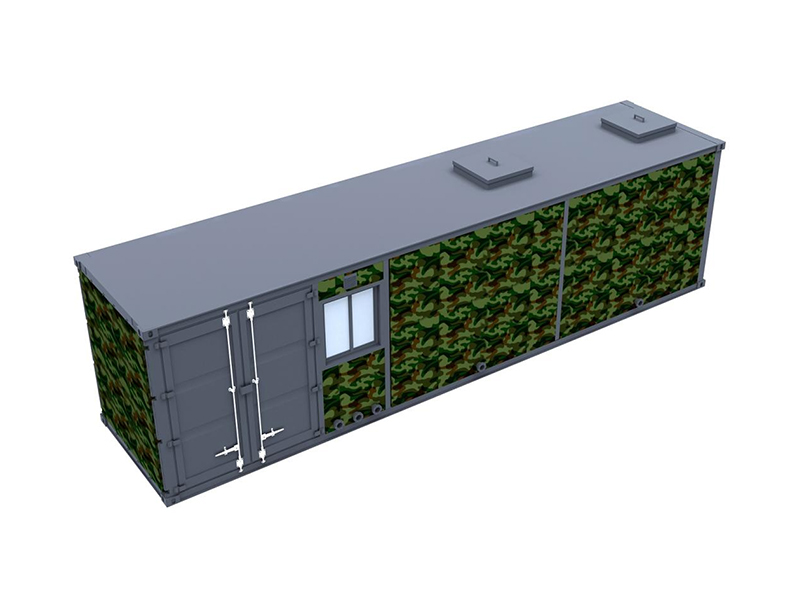

Remote operation control system

Remote operation control system

To meet the needs of water quality monitoring, maintenance warning, data storage, operation monitoring, safety defense, fault feedback, remote operation and maintenance, and truly achieve automatic operation and unmanned operation of water treatment stations through remote centralized intelligent management and low-cost operation and maintenance management.

System Explanation

(1) Water quality monitoring system: can be configured with water quantity, gas volume, temperature, dissolved oxygen, residual chlorine, liquid level, sludge solubility, pressure, negative pressure, ORP, pH, SS, visual sensors, as well as functional modules such as ammonia nitrogen, total nitrogen, total phosphorus, COD, BOD, etc. to achieve real-time monitoring of incoming and outgoing water quality.

(2) Maintenance warning system: Timely display abnormal information such as security, inspection, work orders, attendance, etc. on monitored data, and maintain warnings.

(3) Data storage system: Timely copy and upload device data generated by the site to cloud storage for querying historical data.

(4) Operation monitoring system: can display real-time data and reports of site monitoring items, and can be remotely controlled.

(5) Security defense system: It can be equipped with security terminals for real-time video or remote image capture, providing 24-hour comprehensive defense for equipment.

(6) Fault feedback system: By monitoring and analyzing on-site data, it can provide timely feedback on different faults generated by the equipment.

(7) Remote operation and maintenance system: capable of daily inspection and submission of maintenance content; View work orders and submit processing results; Submit the site assessment results.

Automatic control system upgrade and renovation

Automatic control system upgrade and renovation

The automation system after network upgrade, equipment replacement, line upgrade, and software upgrade is composed of a big data platform, closed-loop linkage control system, process optimization intelligent control, equipment PHM maintenance system, IoT Internet of Things platform, and 3D visualization modern management platform.

Upgrade advantages

(1) To achieve high-quality, low-cost, stable and reliable operational methods;

(2) Centralized display of process fl ow and real-time monitoring of equipment operation status;

(3) Complete fault alarm function and alarm display function;

(4) After upgrading, achieve full automation and realize the advantages of unmanned operation.

Composition of self-control system

(1) Big data platform: covering automated real-time data collection, information maintenance management, information personnel management, cloud configuration, etc.

(2) Closed loop linkage control: dynamically display the real-time operating conditions of various process flows, process equipment, and high and low voltage distribution equipment, and display production data of various processes and electrical equipment.

(3) Process optimization intelligent control: an intelligent control software platform that handles complex algorithms and business logic. It can provide logical redundancy control strategies for the self-control system and provide technical support for achieving stable and intelligent operation of the self-control system.

(4) Equipment PHM maintenance refers to the use of sensor technology to obtain equipment operation status information and fault information. Based on system historical data, big data is used to monitor the equipment's status, evaluate its health status, and provide maintenance suggestions to assist in management and improve design functions.

(5) IOT IoT platform: Data synchronization is achieved through SDN, supporting uplink big data upload, downlink access to various terminal devices, and permission management. Provide a digital foundation for water urbanization.

(6) 3D visualization management platform: 3D modeling and monitoring camera display, comprehensively controlling the operation status of the self-control system.

-

Equipment Technology Introduction - Domestic Sewage Treatment and Reuse Equipment

-

Industrial pure water treatment equipment

-

Equipment Technology Introduction - Organic Wastewater Treatment Equipment

-

Groundwater softening device

-

Intelligent integrated prefabricated pumping station

-

Smart construction site mud water treatment technology and integrated equipment

-

Groundwater iron and manganese removal filter

-

Potable water equipment

-

Smart water management