Superhydrophobic surfaces have broad application prospects in many fields such as waterproofing, anti fog, self-cleaning, corrosion resistance, anti icing, and flow resistance reduction due to their special properties. However, it is still challenging to mass produce low-cost, low toxicity, easy to apply, and durable superhydrophobic coatings.

In nature, there are a large number of calcium carbonate based materials with superior mechanical properties and simple components, which have aroused widespread interest among scientists. Based on in-depth research on the nucleation and growth mechanisms of calcium carbonate, the regulation of biomineralization has been achieved, which has broad application prospects in many fields such as anti fouling, anti scaling, self-cleaning, and oil-water separation.

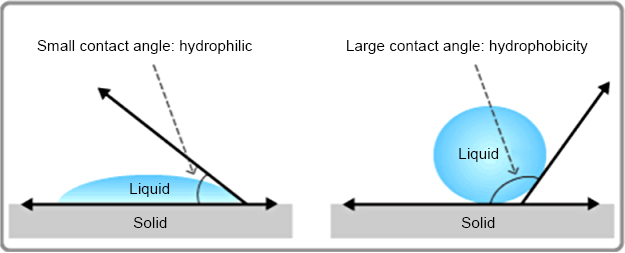

The close relationship between solid particle contact angle and hydrophobicity

Numerous studies have shown that low surface energy and rough structure are the main influencing factors on superhydrophobicity, and these have always been the main research topics of calcium carbonate modification technology. Simply put, the modification direction of calcium carbonate is to reduce surface energy and maintain dispersibility; Increase the contact angle to ensure hydrophobicity.

What kind of calcium carbonate is more suitable for functional coatings? How to modify it? What is the actual effect?

Gu Weile et al. synthesized two different crystal forms of calcium carbonate powders, which were then blended with low surface energy polydimethylsiloxane (PDMS) to spray a superhydrophobic coating. Their self-cleaning ability and impact resistance were tested. Experiments have shown that when the dosage of sodium stearate (NaSt) and sodium oleate (NaOL) surfactants is 5%, the modification effect and hydrophobicity of calcium carbonate are the best. The contact angle of aragonite type calcium carbonate modified by 5% sodium stearate is 127.5 °, and the contact angle of calcite type calcium carbonate modified by 5% sodium oleate is 115.4 °. Further research was conducted on the effect of different amounts of crystalline calcium carbonate on the hydrophobicity of coatings, with contact angles of 151.4 ° and 153.2 ° for calcite and aragonite type calcium carbonate coatings, respectively. Finally, the self-cleaning and impact resistance properties of superhydrophobic coatings were studied. The results showed that after a 500mL water droplet impact test, the contact angle of the two crystalline calcium carbonate superhydrophobic coatings remained above 140 °, maintaining excellent hydrophobicity.

Cheng Yuan et al. used calcium carbonate whiskers (CCWs) and nano calcium carbonate (CCNPs) as fillers to prepare superhydrophobic coatings through powder surface modification, optimization of coating ratio, reference to the "primer topcoat" and polishing methods in coating construction technology. Research has shown that when subjected to 15 cycles of friction, the contact angle of the coating can reach 153.88 °, and the rolling angle can reach 9.20 °. The coating has good self-cleaning performance and can be manually repaired.

What substrate surfaces can calcium carbonate functional coatings be applied on?

1. Fibre

The wet coating technology based on waste polyamide fibers is currently the main method for preparing coated textiles such as trademark ribbons, and it is also an important way for the physical recycling of polyamide fibers. It has the characteristics of low production cost and excellent product performance. Calcium carbonate is a cheap, non-toxic, and harmless inorganic powder widely used as a filler in the wet coating technology of polyamide waste fibers, which can increase the thickness, whiteness, and strength of the surface coating of trademark woven tapes.

Lei Pengfei et al. used oleic acid in-situ synthesis method to prepare coating filler calcium carbonate, which was applied to polyamide wet coating. The contact angle of the coating film decreased by 8.29 °, the ink length of the coated fabric decreased by 10.42mm, and the pH value of the coated fabric decreased to 7.27. The ink absorption was improved, and the pH value was more in line with textile safety standards.

Jiang Jikang et al. used a synthetic modifier DOPO to graft modified calcium carbonate, achieving uniform dispersion in polyamide coatings with clear and fluffy coating pore structures; The pH of the coated fabric in a humid environment is 7.02, which meets environmental requirements. The ink absorption time is 89 seconds, the ink length is 53.4mm, the printed barcode is clear and free of breakage, and the rating reaches A level.

Chen Zhijie et al. used coupling modifiers containing silicon phosphorus flame retardant components to surface graft modify calcium carbonate to enhance dispersion and endow it with flame retardant function, and successfully constructed a smooth and flat porous, thin polyamide coating on the fabric. Research has shown that modified calcium carbonate has good lipophilicity, and its polyamide 6 coated fabric has a good flame retardant effect.

2. Concrete

Surface coating technology is an effective measure to improve the durability of concrete, and superhydrophobic coatings with waterproof, anti icing, and self-cleaning properties are currently one of the research hotspots.

Xu Huafeng et al. used polydopamine to induce calcium carbonate mineralization on the surface of concrete and reduce silver ions in situ to nano silver, in order to construct micro nano composite rough structures. They hydrophobic modified them with low surface energy silane to obtain functionalized calcium carbonate biomimetic superhydrophobic coatings. The results showed that in both normal and simulated seawater environments, the volume water absorption of the composite coating samples decreased by 90.3% and 93.44% compared to the untreated samples, respectively, demonstrating good waterproof and impermeable properties. After repeated friction of the composite coating sample on the sandpaper surface for an equivalent distance of 5 meters, the contact angle of the coating is still greater than 140 °, with a decrease of only 6.87%, demonstrating good wear resistance.

In order to improve the anti-corrosion and pollution resistance of outdoor sandstone buildings, Wen Yaping et al. synthesized a calcium carbonate based fatty acid modified coating using calcium carbonate as the base material and fatty acids as hydrophobic modification materials through liquid phase reaction. Research has shown that the average grain size of octadecanoic acid modified vaterite calcium carbonate is relatively large (31nm), and the surface roughness of sandstone varies greatly. The hydrophobic angle can reach 119 °, the pollution resistance level is 5, and the water absorption rate is only 1.0%. Compared with unmodified coating treated sandstone samples, it effectively improves the surface pollution resistance of sandstone.

3. Glass

Yuan Zhiqing et al. developed a simple and feasible method for preparing polydimethylsiloxane (PDMS)/CaCO3 based on superhydrophobic coatings. The obtained coating can be applied to different substrates, such as kraft paper, glass slides, and copper plates. After coating on a glass substrate and drying at room temperature, the contact angle of the coating surface can reach 160 °, and the sliding angle is less than 3 °. The shear test shows that the superhydrophobic P3 coating has high mechanical shear resistance and adhesion, and can obtain a stable superhydrophobic surface. Outdoor experiments have shown that the preparation of self-cleaning coatings using silicone resin and calcium carbonate modified with stearic acid can retain more than 85% of the transparency of glass panels, with a contact angle of about 110 ° and good anti fog performance. After being exposed outdoors for 4 months, the self-cleaning performance is basically not damaged.

4. Metal

At present, the self-cleaning behavior of wall panel materials is highly concerned, and this self-cleaning behavior can usually be achieved by constructing hydrophobic surfaces. Liu Changyang et al. uniformly deposited a layer of calcium carbonate film about 20 microns thick on the surface of magnesium neodymium alloy, improving the corrosion resistance of the alloy in simulated concrete pore fluids containing chloride ions. The use of perfluorodecyltriethoxysilane for chemical modification of coated samples can enhance their self-cleaning ability.

5. Conclusion

At present, there have been application cases of calcium carbonate functional coatings in many fields such as packaging, tableware, building materials, environmentally friendly materials, textiles, coatings, pharmaceuticals, etc. With the increasing demand for cost reduction and efficiency improvement in enterprises, the application of calcium carbonate functional coatings will become increasingly widespread in the future, and the application technology will gradually mature.

References

Gu Weile, et al.: Research on Crystal Type Control and Application in Superhydrophobic Coatings during in situ Surface Modification of Calcium Carbonate, Hubei University

Yu Shaokang et al.: Biomimetic mineralization regulation and application research of inorganic mineral calcium carbonate, Yanshan University

Cheng Yuan, et al.: Preparation of super hydrophobic coating by calcium carbonate whisker composite nanoparticles, University of Chinese Academy of Sciences

Xu Huafeng, et al.: Research on Functionalized Mineralized Composite Coatings and Durability of Coastal Concrete Surface, Qingdao University of Technology

Wen Yaping, et al.: Preparation and Modification of Sandstone Protective Material Calcium Carbonate, Yunnan University

Yuan Zhiqing, et al.: Preparation of polydimethylsiloxane (PDMS)/CaCO based on superhydrophobic coatings, Hunan University of Technology

Lei Pengfei, et al.: In situ synthesis of calcium carbonate from oleic acid and its application in polyamide wet coating, Zhejiang University of Technology

Jiang Jikang et al.: Synthesis of DOPO Si modified calcium carbonate and its application in polyamide wet coating, Zhejiang University of Science and Technology

Chen Zhijie et al.: Synthesis of Silicon Phosphorus Modified Calcium Carbonate and Its Application in Polyamide Coatings

Note: The image is not for commercial use and there is infringement notice. Please delete it! Source: Powder Net

Post time: May-22-2024