In response to the current situation of poor quality and short service life of equipment in the environmental protection industry, weak technology, substandard processing, lack of professional personnel, difficulty in operation and maintenance, idle systems, low equipment prices, high civil engineering costs, high overall costs, and the emergence of fake technologies, as well as the falsification of water quality data, Our company's independently developed intelligent landscape integrated sewage treatment and reuse equipment based on the "ST reverse thrust efficient denitrification+aerobic MBR" technology has obvious advantages and has been widely applied, establishing a good reputation.

The core of the "ST reverse push efficient

nitrogen removal+aerobic MBR" technology mainly lies in four aspects:

1. ST - reverse thrust high-efficiency nitrogen

removal technology;

2. Aerobic MBR membrane technology;

3. Remote monitoring and control technology on

cloud platforms;

4. The equipment comes with insulation

technology.

Core Technology 1: ST Reverse Push High Efficiency Nitrogen Removal

Basic Theory

The denitrification theory based on short-range nitrification denitrification, AAO process, AAAO process, two-stage or multi-stage AO process.

Regional coexistence of dominant bacterial communities

There are a large number of aerobic bacteria, nitrifying bacteria, nitrite bacteria, and denitrifying bacteria coexisting in the ST reverse thrust high-efficiency denitrification process section. The reverse thrust design allows for repeated denitrification reaction cycles.

Outstanding advantages (on-site statistics of successful cases from data sources)

20% reduction in alkali dosage, 30% reduction in denitrification tank volume, 20% reduction in energy consumption, 40% reduction in carbon source dosage, and 30% reduction in sludge volume.

Core Technology 2: Aerobic MBR Technology

Biological contact oxidation technology

The biological filler and aeration device form an aerobic reaction functional zone, providing attachment points for aerobic microorganisms. Measures such as aeration are used to maintain dissolved oxygen in water, which is suitable for the growth and reproduction of aerobic microorganisms, thus treating pollutants in water.

Aerobic MBR technology

Comprehensively combined with biological fillers, membrane components, and aeration devices, it has an aerobic reaction functional zone and a regional MBR membrane separation zone, alleviating the blockage of MBR membrane due to high sludge concentration, balancing the overall sludge concentration, and improving the ability to withstand impact loads.

MBR membrane bioreactor technology

The

MBR membrane module, combined with the aeration device, forms the MBR membrane

functional area, which is a new and efficient wastewater treatment process that

combines high-efficiency membrane separation technology with traditional

activated sludge method.

Core Technology 3: Cloud Platform Remote Monitoring and Control Technology

The cloud platform remote monitoring and control technology realizes the remote monitoring and control function. The system integrates PLC logic control cabinet, 4G network transmission gateway, fault sensor, status sensor, and mobile APP, realizing unmanned and automatic operation. If there is a fault, automatic alarm can be triggered and remote control can be used to cooperate with on-site troubleshooting. A dedicated person can be configured to be on duty 24 hours a day, so that in the absence of on-site management, Maximize the normal operation of the equipment. The system has a high degree of automation and adopts PLC control, which can achieve full automation control.

Core Technology 4: Equipment comes with insulation technology

For cold regions, intelligent landscape integrated sewage treatment and reuse equipment can be equipped with insulation technology modules. It not only uses 100mm high-density polyurethane insulation boards and other materials to insulate the equipment body, but also adds 16mm metal heat absorbing carved boards. The equipment comes with insulation to reduce the high construction cost of building greenhouses for insulation in civil engineering projects.

Characteristic

The intelligent landscape integrated sewage treatment and reuse equipment based on the "ST reverse push efficient deoxygenation+aerobic MBR" technology has the following characteristics:

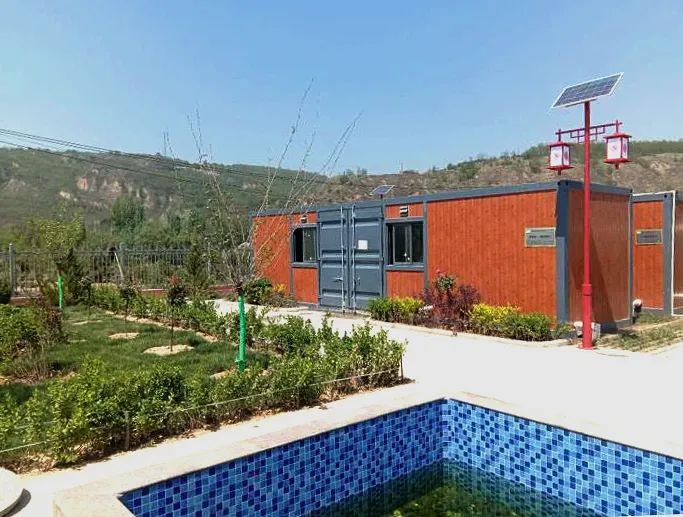

1. The equipment frame structure is aesthetically pleasing with high strength, and the station area achieves landscaping.

2. Mature core technology, strong impact resistance, and can achieve 100% stable compliance.

3. The cost of supporting civil engineering is very low, and there is no need to build insulation greenhouses in northern regions.

4. Including the owner's supporting projects, the overall project cost is still less than 10% compared to peers.

5. The process is concise, easy to maintain, and has low operating costs; The equipment has strong impact resistance, high stability, and good effluent quality; High degree of automation, capable of online monitoring and unmanned operation; Tailored to local conditions, with strong adaptability; And multiple stable benchmark demonstration projects have been established.

Case presentation

Application scope and target customers

The intelligent landscape integrated sewage treatment and reuse equipment based on the "ST reverse push efficient deoxygenation+aerobic MBR" technology is widely used, and can be used in rural townships, industrial parks, medical institutions, highway service areas, tourist resorts, and places with insufficient municipal sewage treatment facilities.

Certificate display

Post time: Dec-25-2023