1、Product Introduction

MBR membrane bioreactor is a new sewage treatment process that combines membrane separation technology with traditional activated sludge method. It uses MBR membrane components with unique structures to be placed in an aeration tank. After aerobic aeration and biological treatment, the water is pumped through a filter membrane and then extracted. MBR sewage treatment differs greatly from traditional sewage treatment methods by replacing the secondary sedimentation tank and tertiary treatment process in traditional processes through membrane separation and transposition. The resulting effluent solves the problem that the effluent quality of traditional environmental protection equipment for sewage treatment cannot reach the level of recycled water.

2、Product advantages

The MBR membrane bioreactor component series has the advantages of compact structure, beautiful appearance, small footprint, low operating cost, stability and reliability, high degree of automation, and convenient maintenance and operation. The effluent quality of MBR sewage treatment is good, better than the standard of reclaimed water quality, and it is currently an internationally advanced sewage treatment equipment. MBR integrated equipment is an integrated equipment that utilizes membrane bioreactors for wastewater treatment and reuse. It has all the advantages of membrane bioreactors: good effluent quality, low operating costs, strong system impact resistance, low sludge volume, and high degree of automation. Moreover, as an integrated device, it has the characteristics of small footprint and easy integration.

3、Working principle

Membrane bioreactor (MBR) process is a new type of wastewater treatment technology that combines membrane separation technology with biotechnology. It uses membrane separation equipment to trap the activated sludge and macromolecular organic matter in the biochemical reaction tank, eliminating the need for a secondary sedimentation tank. The concentration of activated sludge is greatly increased as a result, and the hydraulic retention time and sludge retention time can be controlled separately, while difficult to degrade substances continuously react and degrade in the reactor.

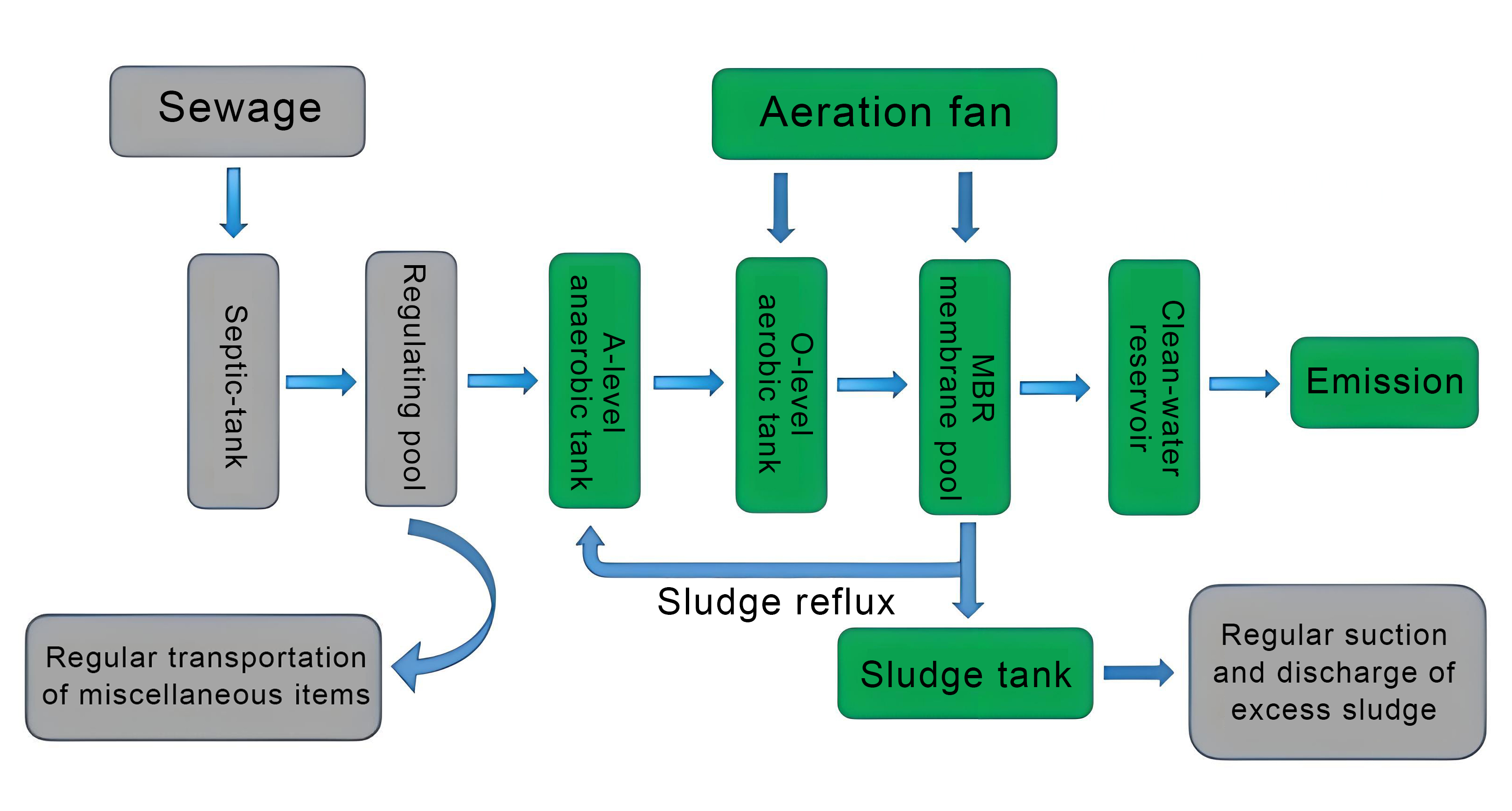

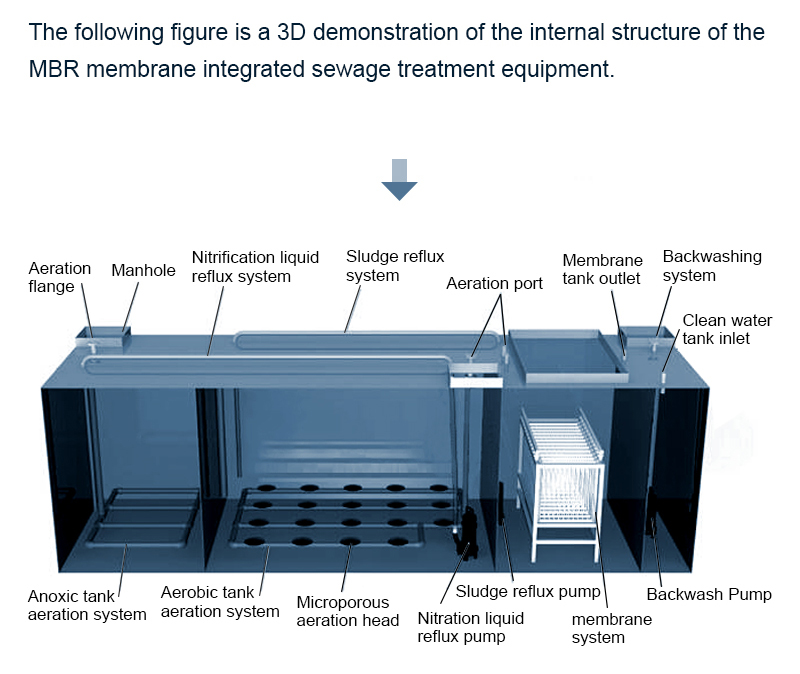

Process Flow Diagram

Process flow diagram of MBR integrated equipment for treating domestic sewage

4、Process characteristics

(1) Degradation of organic matter in wastewater, nitrification of NH3-N to N03- by nitrifying bacteria, with a removal rate of over 95% for organic matter; The removal rate of ammonia nitrogen is above 97%;

(2) The pre-treatment process is simple, without the need for a large amount of chemical agents, and the operation process is simple;

(3) The recovery rate is high, and the water recovery rate can reach over 99%. This flexibility allows operators to reduce the "pressure" on the diaphragm by reducing the recovery rate when the quality of the incoming raw water deteriorates, but at the same time produce the same amount and quality of purified water;

(4) The system uses logical process monitoring, including flow transmitters and pressure transmitters, among others. This highly controlled system approach can be used to design flexible systems and improve the low requirements for operator interfaces;

(5) Air flushing ensures reliable operation under various inflow conditions;

(6) Automatic recoil ensures an increase in overall membrane flux at lower membrane pressure;

(7) Small footprint, only 10-20% of traditional craftsmanship;

(8) Long service life, continuous operation time can reach 70000 hours, and wire breakage rate is less than 1%.

Post time: Dec-25-2023