The composition of general industrial wastewater is relatively complex, and heavy metals may exceed the limit in industries such as mining, mechanical manufacturing, chemical, electronics, and instrumentation. How are heavy metals usually treated and what are the methods?

Heavy metals in wastewater generally cannot be decomposed or destroyed, and can only be transferred to their existing positions and transformed into their physical and chemical forms. The treatment method is to first reform the production process and avoid or reduce the use of highly toxic heavy metals;

Chemical precipitation, ion exchange, electrolytic recovery, membrane method, etc. are commonly used for on-site treatment at the production site (if not discharged from the production workshop). The treated water can be discharged or reused if the heavy metals are below the discharge standards.

01 Chemical precipitation method

Add heavy metal capture agents to improve removal efficiency. At present, most domestic electroplating enterprises use various electroplating treatment processes to treat wastewater, but the wastewater still cannot meet the standards. In this case, heavy capture agents can be directly added to the flocculation tank of the original process.

02 Ion exchange method

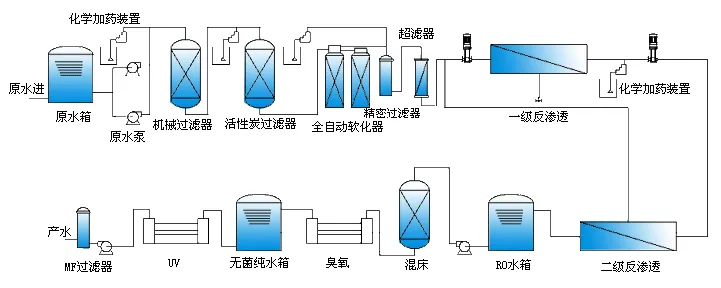

Ion exchange mainly uses hard water softening and deionization methods, using ion exchange resin to filter the raw water. The ions in the water will exchange with the ions fixed on the resin;

After ion exchange, membrane filtration is carried out, and then a heavy capture agent can be added to the chemical dosing device for efficient flocculation and sedimentation. Finally, filtration and disinfection are carried out to meet the water treatment standards.

Technological process:

03 Electrolytic recovery method

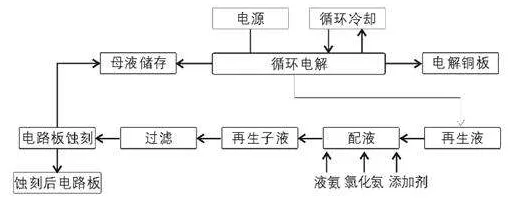

Electrolytic recovery mainly utilizes the electrochemical properties of metals. During the electrolysis process, pollutants undergo oxidation and reduction reactions on the positive and negative electrodes respectively, which then transform into non-toxic and harmless chemicals or generate insoluble precipitates, thereby achieving the effect of removing heavy metals.

Technological process:

04 membrane method

There are mainly electrodialysis and reverse osmosis methods. The characteristic of electrodialysis is that the concentration factor is limited, and it requires multi-stage electrodialysis treatment to concentrate useful substances in wastewater to a recyclable level.

Reverse osmosis method is used to treat electroplating rinsing wastewater such as nickel plating, copper plating, zinc plating, cadmium plating, etc. The removal efficiency of nickel, copper, zinc, and cadmium plasma is mostly greater than 99%.

Therefore, heavy metal wastewater can be concentrated and reused through reverse osmosis treatment, and can also be reused when the quality of reverse osmosis water (produced water) is good.

The selection of appropriate heavy metal treatment methods depends on the nature, concentration, and treatment requirements of the wastewater. How to treat industrial wastewater with excessive heavy metals requires the development of reasonable solutions based on the wastewater site to ensure that the treated wastewater meets the discharge standards.

Post time: Jul-10-2024