The membrane bioreactor method for treating urban and industrial organic wastewater has been widely used in wastewater treatment and resource utilization engineering due to its high efficiency, energy conservation, no phase change, no secondary pollution, good output water quality, small land occupation, and high degree of automation, and has shown broad development prospects. The membrane bioreactor method is used to treat urban and industrial organic wastewater, with an investment of 2000-4000 yuan/ton of water and an operating cost of less than 1.50 yuan/ton of water. The environmental and economic benefits are very significant!

1. Control of MBR influencing factors

In the membrane bioreactor process, the operating conditions for membrane separation are similar to traditional membrane separation, and the main control factors include inlet water quality, membrane surface flow rate, temperature, operating pressure, pH value, MLSS, etc.

(1) Temperature

The membrane bioreactor system should be operated at 15 ℃ to 35 ℃. Usually, as the temperature rises, the membrane flux increases, mainly because the viscosity of the activated sludge mixture is reduced after the temperature rises, thereby reducing the permeation resistance.

(2) Operating pressure

Under the condition that the characteristics of the activated sludge mixture remain basically unchanged, the membrane flux increases with the increase of pressure; But when the pressure reaches a certain value, that is, concentration polarization causes the solute concentration on the membrane surface to reach the limit concentration, continuing to increase the pressure can hardly improve the membrane flux, but instead exacerbates membrane fouling and blockage. The transmembrane pressure difference of submerged MBR should not exceed 0.05MPa.

(3) Dissolved oxygen

Dissolved oxygen is an important factor affecting the removal efficiency of organic matter. Especially for the purpose of phosphorus and nitrogen removal, controlling the concentration of dissolved oxygen is particularly important. In different types of membrane bioreactor processes, the mixed liquid forms aerobic, anoxic, and anaerobic sections in various forms within the bioreactor. The control range of DO in each section of the reaction tank is: the anaerobic section should be below 0.2mg/L, the anaerobic section should be between 0.2mg/L and 0.5mg/L, and the dissolved oxygen concentration in the aerobic section should not be less than 2mg/L.

(4) Membrane surface flow velocity

The influence of membrane flow velocity and pressure on membrane flux is interrelated. When the pressure is low, the membrane surface flow rate has little effect on the membrane flux, while when the pressure is high, the membrane surface flow rate has a significant impact on the membrane flux. As the membrane flow rate increases, the membrane flux also increases, especially when the pressure is relatively high. This is because increasing the membrane surface flow velocity can increase the shear force of the water flow and reduce the deposition of pollutants on the membrane surface; On the other hand, increasing the flow rate can improve the convective mass transfer coefficient, reduce the thickness of the boundary layer, and reduce the influence of concentration polarization. In addition, the degree of influence of membrane flow rate on membrane deposition layer is also related to the sludge concentration in the feed solution. When the sludge concentration is low, the membrane permeation rate increases linearly with the membrane flow rate. But when the sludge concentration is high, the impact on the sedimentation layer weakens and the rate of increase in membrane flux decreases when the membrane surface flow rate increases to a certain value. For external MBR, the operating conditions should be controlled at low pressure and high flow rate as much as possible, and the membrane flow rate should be maintained at 3m/s to 5m/s. This is not only beneficial for maintaining a high water flux, but also for membrane maintenance and upkeep, reducing membrane cleaning and replacement.

(5) MLSS

The sludge concentration in the submerged MBR aerobic zone (tank) should be controlled between 3000mg/L and 20000mg/L. Generally speaking, at a certain membrane flow rate, when the sludge concentration in the feed liquid increases, due to the high sludge concentration, the sludge is prone to deposit on the membrane surface to form a thick sludge layer, leading to an increase in filtration resistance and a decrease in membrane flux. However, the concentration of sludge in the feed solution should not be too low, otherwise the degradation rate of pollutants will be low. At the same time, the adsorption and degradation ability of activated sludge for dissolved organic matter will weaken, resulting in an increase in the concentration of dissolved organic matter in the supernatant of the mixed solution, which is easily adsorbed by the membrane surface, leading to an increase in filtration resistance and a decrease in membrane flux. Therefore, it is necessary to maintain a moderate sludge concentration in the feed liquid, as either too high or too low will reduce the water flux.

(6) PH value

The pH value of the inlet water in the membrane bioreactor should be 6-9.

2. MBR Biochemical Process Control

When the inlet water temperature is below 8 ℃, the activity of activated sludge is affected to a certain extent. At this time, the outlet water should be appropriately reduced to ensure that organic matter in the wastewater is fully degraded in the reaction tank, thereby ensuring the quality of the effluent. Reduce membrane blockage.

In seasons with sudden changes in temperature, it is particularly important to observe the effluent quality. If there is a sudden change in effluent quality, it is necessary to reduce the appropriate amount of water and increase the aeration time.

During normal operation, efforts should be made to avoid mixing disinfectants and disinfectants that have inhibitory effects on microbial metabolism into the bioreactor. Prevent the normal biological mechanisms of microorganisms in the equipment from being disrupted, leading to deterioration of the effluent.

When the sewage contains a large amount of synthetic detergent or other foaming substances, a large amount of foam will appear in the membrane biological reaction tank, which can be solved by spraying water, but do not add defoamer containing oily substances to the reaction tank to remove foam. Silicone series defoamers should also not be used. The silicone series defoamers are adsorbed onto the surface of the membrane, which accelerates the increase of differential pressure between membranes and causes membrane blockage. At this point, it is difficult to restore the pressure difference even when using liquid medicine for cleaning, and the membrane needs to be replaced.

The MBR process system should regularly discharge a certain amount of residual sludge. The sludge discharge can be determined based on the sludge settling ratio, mixed liquid sludge concentration, organic load of activated sludge, or sludge age.

3. Control of MBR membrane fouling and cleaning

Membrane fouling is the phenomenon where suspended particles, colloids, and other substances in wastewater deposit on the surface of a membrane, causing blockage of membrane pores. Once the membrane comes into contact with the feed liquid, contamination begins, and adsorption occurs due to the interaction between the solute and the membrane, which begins to change the membrane characteristics. For microfiltration membranes, this effect is not very significant, mainly due to the aggregation and blockage of solute particles; For ultrafiltration, improper selection of membrane materials can have a significant impact, reducing the initial pure water flux by 20% to 40%. Especially in the case of low flow rate and high solute concentration, when the solute reaches or exceeds the saturation solubility on the membrane surface, a gel layer will be formed, resulting in the membrane permeability independent of the applied pressure, resulting in a sharp decline in the membrane permeability. Therefore, the membrane operating in this state must be cleaned after use to restore its performance.

The measures to control membrane fouling include:

① Pre treat the influent of the membrane bioreactor system to remove coarse particles;

② Choose the appropriate operating pressure;

③ Shortening the suction time of the water outlet pump, prolonging the stop suction time, and increasing the aeration rate are all beneficial for mitigating membrane fouling.

Air cleaning of the membrane can remove surface impurities, and impurities in the pores can be backwashed with water to remove them. Water backwashing is the process of pumping filtered water from the backwash tank to the suction pipe. Depending on the type of membrane, backwashing is generally performed every 10 minutes to 24 hours.

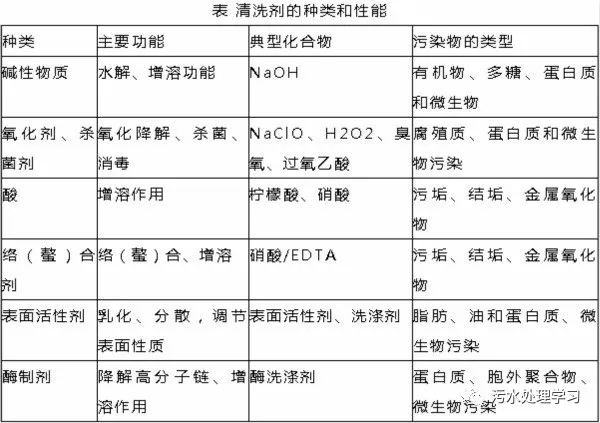

When water backwashing is ineffective, it is necessary to use chemical cleaning methods to remove pollutants in order to maintain the good performance of the membrane. The chemical cleaning of membranes varies depending on the specific situation of pollutants, and the cleaning agents used are also different. The principle of selecting chemicals during chemical cleaning is to avoid any chemical reaction with the membrane and other component materials, and to avoid secondary pollution caused by the use of chemicals.

The categories and properties of commonly used cleaning agents for membrane cleaning are shown in the table below:

Source: Environmentally friendly water treatment

Post time: May-22-2024